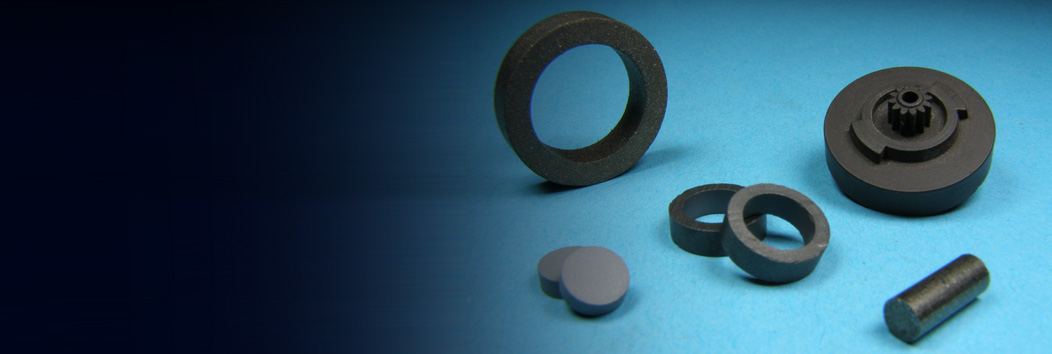

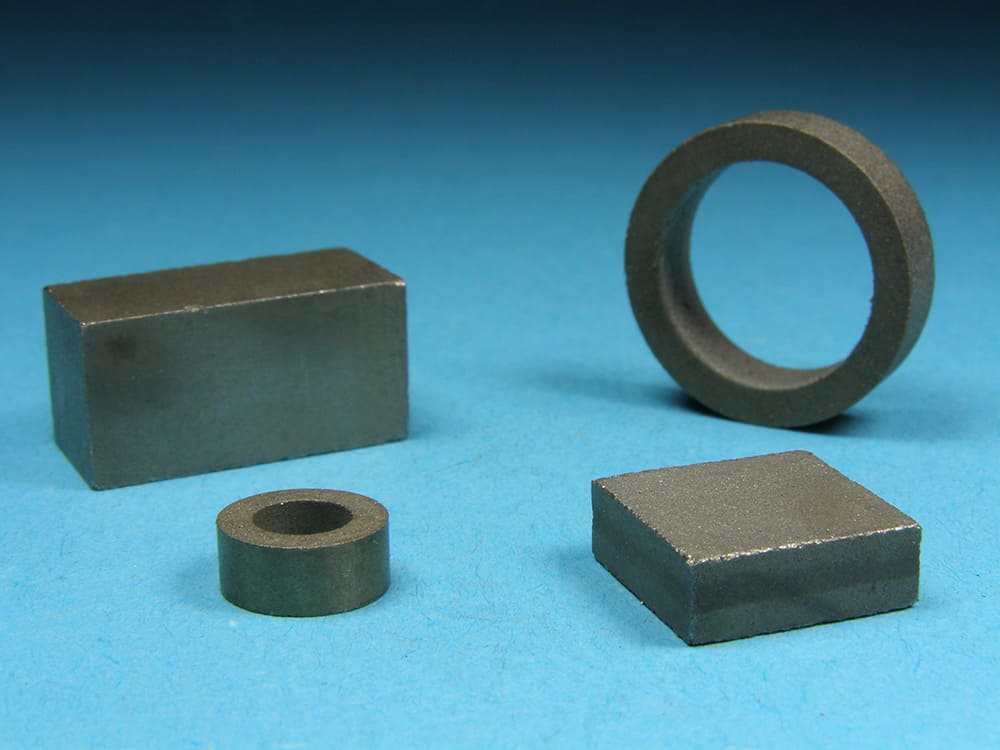

Bonded Magnets

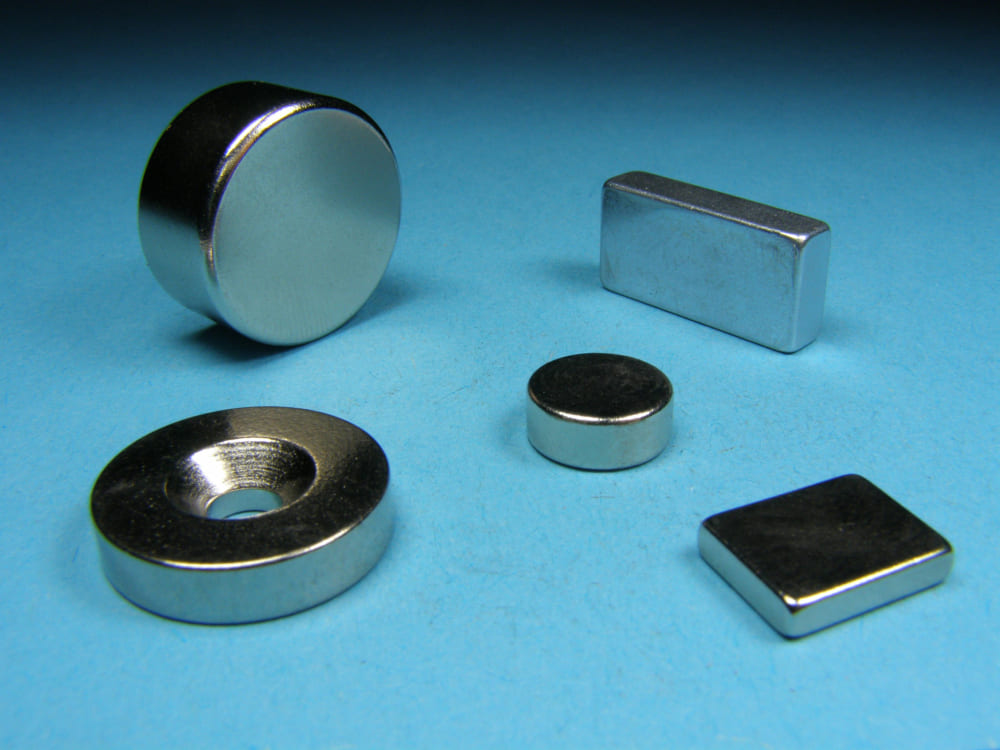

Bonded magnets are produced in a hot compression moulding die. In contrast to usual magnetic material they can be worked on by cutting. Because of their isotropy (i.e. no preferred direction), they can be magnetized in any direction. A slight rust film can occur on unprotected surfaces because of the neodymium. In corrisive conditions we recommend a coating, either paint or plastic.

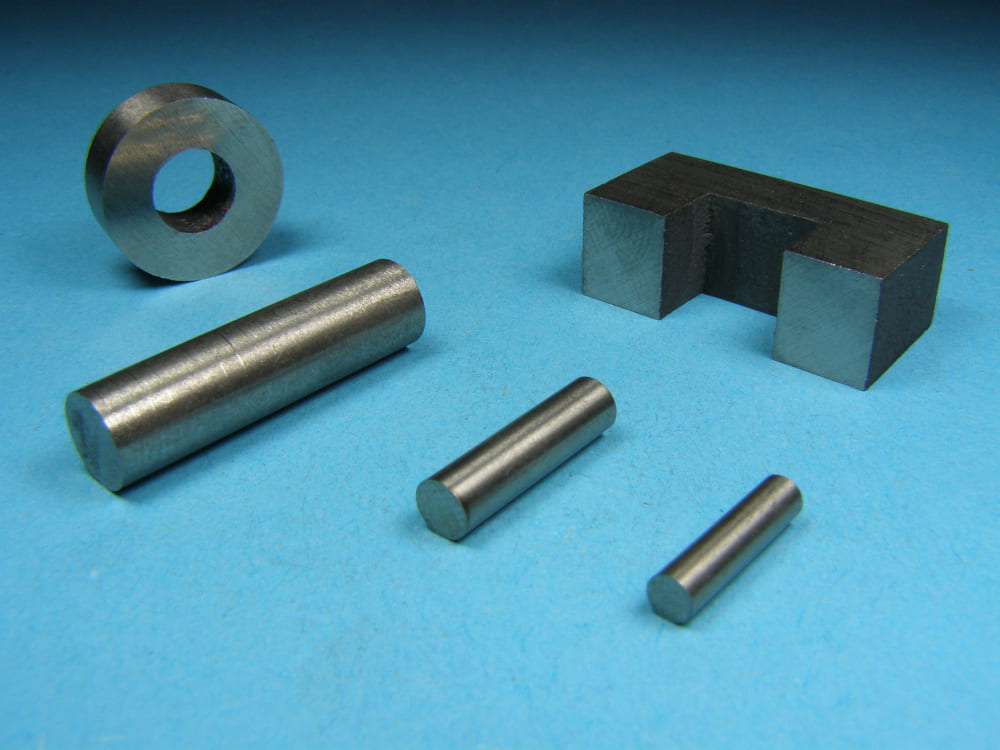

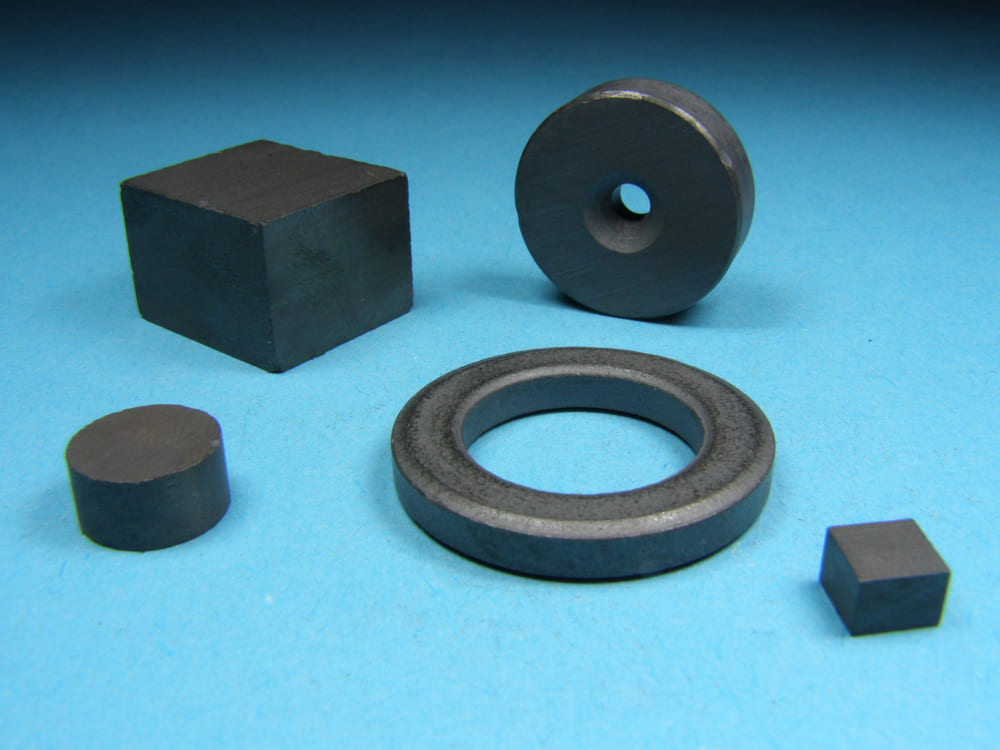

We'Ve got more than 100 different types of rings, cylinders, blocks, segments and special designs at SmCo. Please ask for us about your desired dimensions.

Technical Details polymer-bonded HF Magnets

| Material | Remanence | Energy product | Coercivity field power | max. Working - | |

| Br (typ.) | (BxH)max. (typ.) | HcB (typ.) | HcJ (typ.) | temperature | |

| PE15 | 250 mT | 11,4 kJ/m³ | 177 kA/m | 248 kA/m | 120 °C |

| PE60M | 55 mT | 0,574 kJ/m³ | 41,4 kA/m | 208 kA/m | 250 °C |

Physical and Technical specifications

| Material | Density | Flexural strength | max. Working-temperature | Binder |

| g/cm3 | Mpa | °C | ||

| PE15 | 3,7 | 60 | 120 | Nylon 6 |

| PE60M | 2,4 | 78 | 120 | Nylon 6/66 |

Technical Details polymer-bonded NdFeB Magnets

| Material | Remanence [ ] | Energy Product [kJ/m³ ] | Energy Product [ kA/m] | max. Working - | |

| Br min/max | BHmax min/max | HcB min/max | HcJ min/max | temperature[°C] | |

| BMDT-2 | 200/300 | 16/24 | 240/320 | 400/560 | 160 |

| BMDT-4 | 400/500 | 32/40 | 320/360 | 560/720 | 160 |

| BMDT-6 | 500/600 | 40/48 | 320/360 | 560/720 | 160 |

| BMDT-8 | 600/650 | 60/68 | 360/440 | 640/800 | 160 |

| BMDT-8H | 550/650 | 60-68 | 400/480 | 1040/1360 | 160 |

| BMDT-8L | 600/680 | 64/72 | 400/480 | 640/800 | 160 |

| BMDT-8SR | 580/650 | 60/68 | 400/480 | 880/1120 | 170 |

| BMDT-10 | 680/710 | 76/84 | 400/480 | 640/800 | 160 |

| BMDT-10H | 700/720 | 80/88 | 400/480 | 720/880 | 160 |

| BMDT-12 | 720/770 | 88/96 | 400/480 | 720/880 | 160 |

| BMDT-12D | 720/770 | 88/96 | 440/520 | 800/960 | 160 |

| BMDT-12L | 740/800 | 88/96 | 400/480 | 540/640 | 150 |

Physical and Chemical Specifications

| Material | Hardness | Density | Temperaturecoefficient | Saturation field strength |

| [HRB] | [g/cm3] | [8% / °K] | [kA/m] | |

| BMDT-2 | 40-45 | 3-4 | -0,11 | > 1600 |

| BMDT-4 | 40-45 | 4,5-5,5 | -0,11 | > 1600 |

| BMDT-6 | 40-45 | 5,3-5,8 | -0,11 | > 1600 |

| BMDT-8 | 35-38 | 5,8-6,0 | -0,11 | > 1600 |

| BMDT-8H | 35-38 | 5,8-6,0 | -0,12 | > 2400 |

| BMDT-8L | 35-38 | 5,8-6,0 | -0,12 | > 1600 |

| BMDT-8SR | 35-38 | 5,8-6,0 | -0,13 | > 2000 |

| BMDT-10 | 35-38 | 5,8-6,0 | -0,10 | > 1600 |

| BMDT-10H | 35-38 | 6,0-6,2 | -0,10 | > 1600 |

| BMDT-12 | 35-38 | 6,2-6,5 | -0,10 | > 1600 |

| BMDT-12D | 35-38 | 6,2-6,5 | -0,08 | > 2000 |

| BMDT-12L | 35-38 | 6,2-6,5 | -0,11 | > 1600 |