Magnets of Neodymium-Iron-Boron (NdFeB)

NdFeB Magnets belong to the group of rare-earth Magnets and have got a very high energy efficiency. The availability of raw material is relatively good and therefore the magnets are cheaper than equivalent SmCo products. NdFeB Magnete are very hard, but less brittle than magnets of SmCo. They are used in all types of applications, because systems like spee or motors can be build smaller and more efficient, because of their high energy density. The usage of an anti-corrosive protection is recommended if NdFeB Magnets are used in high-humidity environment. Usually they are zinc- or nickel plated after the production, but it is possible to aply other coatings like epoxyd, gold or tin.

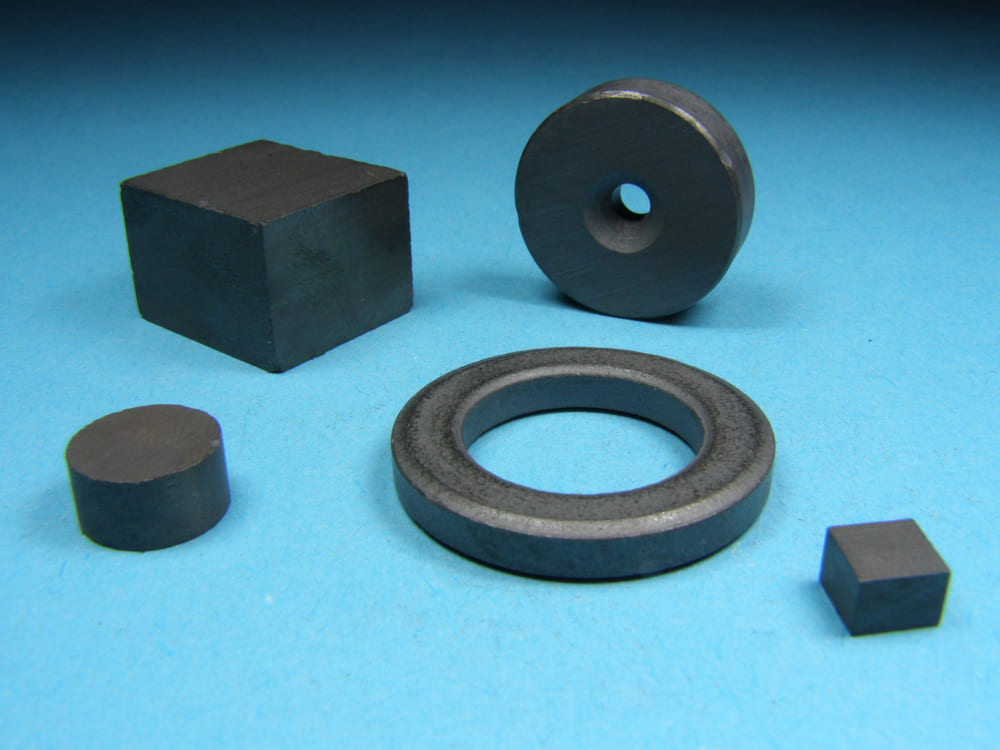

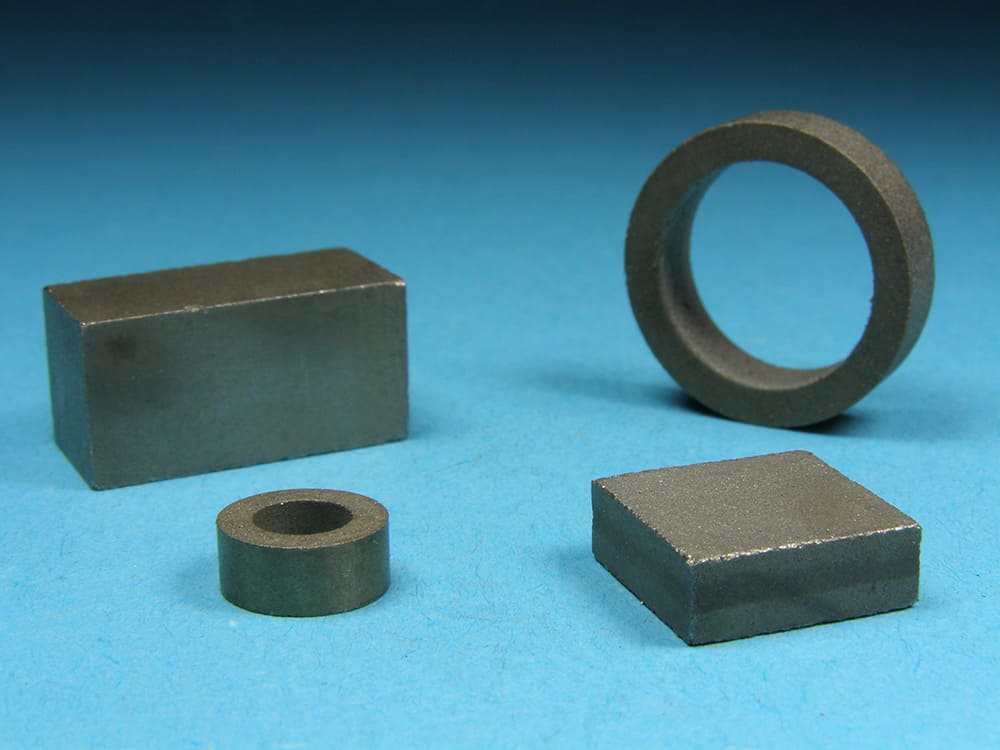

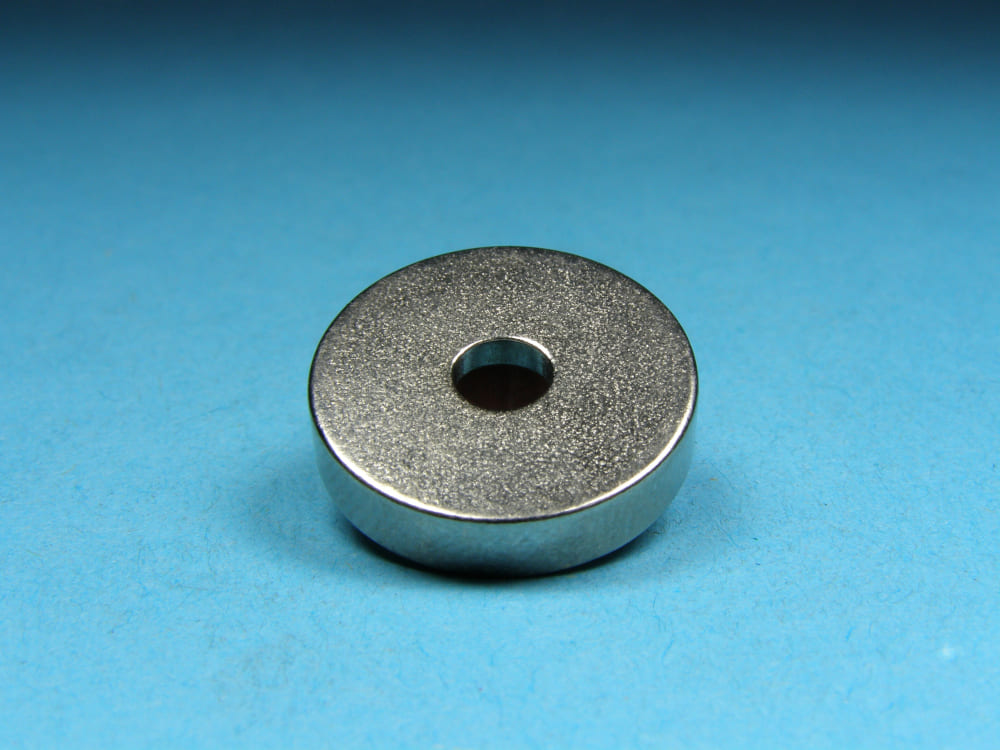

rings

from ø 8 mm to ø 185 mm

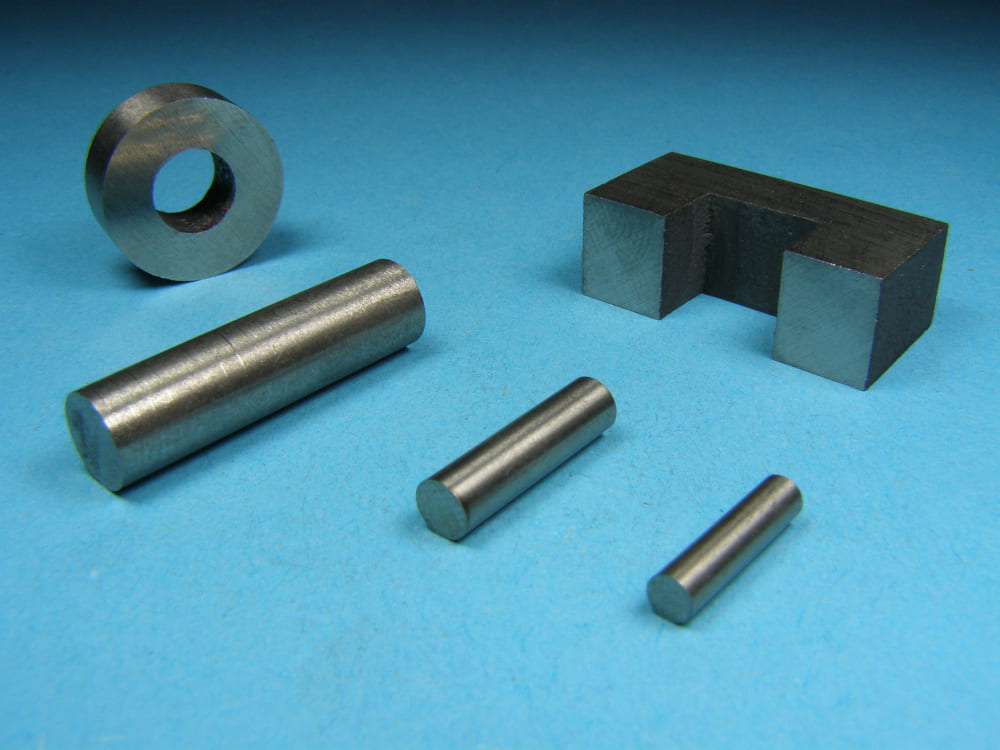

cylinders

from ø 4 mm to ø 90 mm

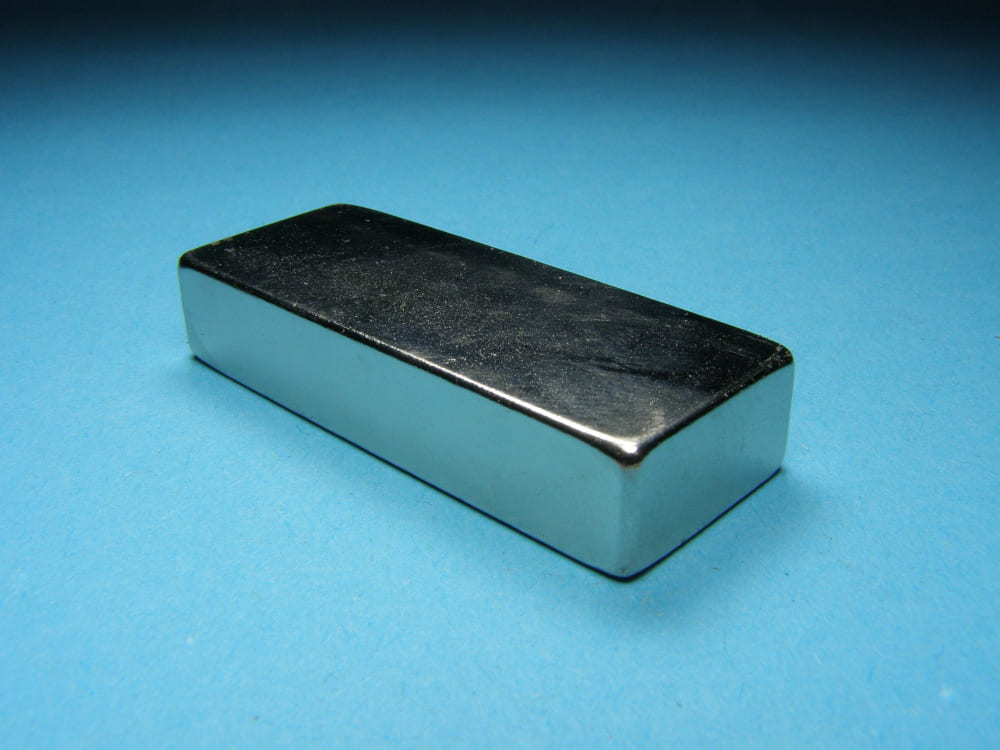

blocks

from 1,2 mm to 150 mm

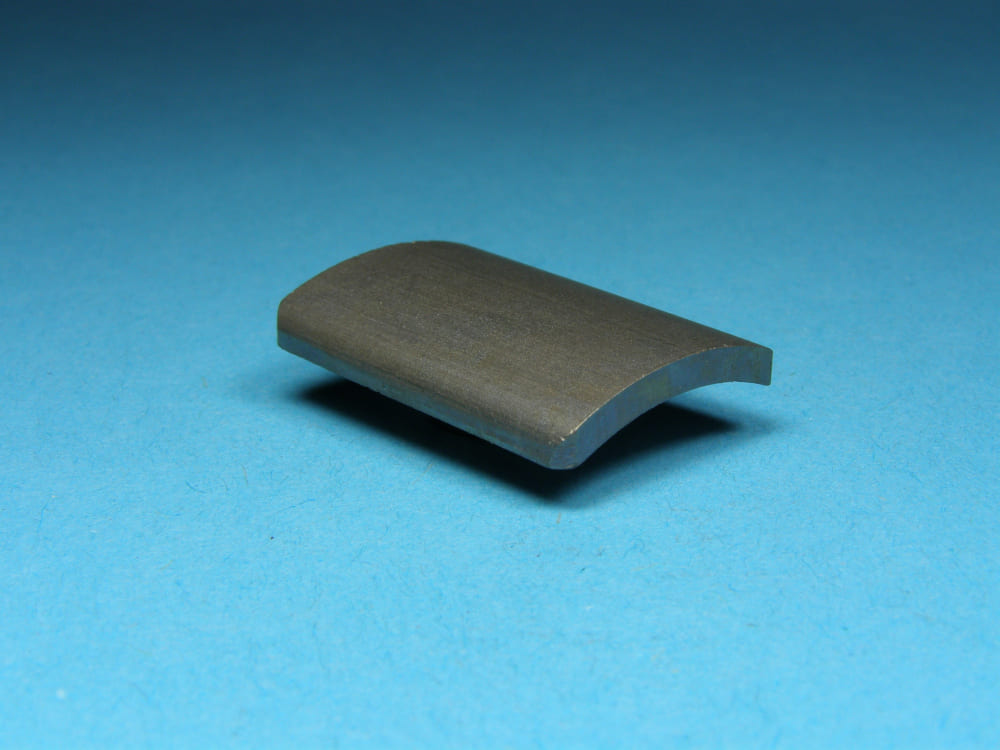

special designs

according to your requirements

We've got more than 150 different types on stock. Please ask for your requested design and size.

Physical and chemical characteristics

Curie-temperature: ~ 330 °C

Specific electric resistance: 1,2 – 1,6 Ohm*mm²/m

Specific heat: ~ 440 J/(kg*K)

Thermal conductivity ~ 9 W/(m*k)

Extension Coefficient: 5 c 10-6/K

E-Modul 150 KN/mm²

Flexural strength: ~ 270 N/mm²

Compressive strength: ~ 1050 N/mm²

Vickers hardness: ~ 570 HV

Fracture toughness: Kic 70 - 90 MPa m0,5

Magnetical data

Material | Remanence | Energy Produkt | Coercivity field power | Working - | |

| Br [mT] | BHmax [kJ/m3] | HcB [kA/m] | HcJ [kA/m] | temperature [°C] |

| min. | min. | min. | min. | max. |

| N27 | 1020 | 199 | 765 | >=955 | 80 |

| N30 | 1080 | 223 | 780 | >=955 | 80 |

| N33 | 1130 | 247 | 820 | >=955 | 80 |

| N35 | 1170 | 263 | 860 | >=955 | 80 |

| N37 | 1200 | 279 | 860 | >=955 | 80 |

| N40 | 1250 | 303 | 844 | >=955 | 80 |

| N43 | 1300 | 326 | 796 | >=876 | 80 |

| N45 | 1330 | 342 | 796 | >=876 | 80 |

| N50 | 1400 | 398 | 812 | >=876 | 80 |

| N30M | 1080 | 223 | 780 | >=1114 | 100 |

| N33M | 1130 | 247 | 820 | >=1114 | 100 |

| N35M | 1170 | 263 | 860 | >=1114 | 100 |

| N37M | 1200 | 279 | 860 | >=1114 | 100 |

| N40M | 1250 | 303 | 844 | >=1114 | 100 |

| N48M | 1370 | 358 | 859 | >=1114 | 100 |

| N27H | 1020 | 199 | 765 | >=1353 | 120 |

| N30H | 1080 | 223 | 780 | >=1353 | 120 |

| N32H | 1120 | 239 | 820 | >=1353 | 120 |

| N35H | 1170 | 263 | 860 | >=1353 | 120 |

| N37H | 1200 | 279 | 915 | >=1353 | 120 |

| N40H | 1250 | 303 | 915 | >=1353 | 120 |

| N46H | 1350 | 438 | 859 | >=1353 | 121 |

| N48H | 1370 | 448 | 859 | >=1353 | 122 |

| N27SH | 1020 | 199 | 765 | >=1595 | 150 |

| N30SH | 1080 | 223 | 780 | >=1595 | 150 |

| N32SH | 1120 | 239 | 820 | >=1595 | 150 |

| N35SH | 1170 | 263 | 860 | >=1595 | 150 |

| N42SH | 1300 | 398 | 859 | >=1592 | 151 |

| N44SH | 1330 | 418 | 859 | >=1592 | 152 |

| N25UH | 970 | 183 | 748 | >=1910 | 160 |

| N28UH | 1040 | 207 | 780 | >=1910 | 160 |

| N30UH | 1080 | 223 | 804 | >=1910 | 160 |

| N38UH | 1220 | 348 | 835 | >=1990 | 160 |

| N40UH | 1260 | 378 | 835 | >=1990 | 160 |

| N35EH | 1170 | 328 | 835 | >=2398 | 180 |

| N38EH | 1220 | 348 | 835 | >=2389 | 180 |

Surface Protection and Coating

Surface | Type | Thickness (min.) [µm] |

| Nickel | Ni + Ni Ni + Cu + Ni | 10 - 20 |

| Zinc | Zn C-Zn | 8 - 20 |

| Tin | Ni + Cu + Sn | 15 - 20 |

| Gold | Ni + Cu + Au | 10 - 20 |

| Copper | Ni + Cu | 10 - 20 |

| Epoxy | Ni + Cu + Epoxy Zn + Epoxy | 15 - 25 |

| Chem. Nickel | Ni | 10 - 20 |