AlNiCo - Magnets

This material was developed in the early 30's of the twentieth century. The most outstanding characteristics of this material are its high application temperature of approx. 500°C and the very low temperature coefficient of 0,02%/°K. Because of their high hardness AlNiCo magnets can be worked on later only by grinding and by eroding.

If you are using the magnet as a single magnet without iron support its length-diameter ratio should be 3 - 7. Because of the advantages mentioned this material is used preferentially in adhesive systems for high application temperatures, signal generators for Hall/Reed Sensors and in measuring instruments.

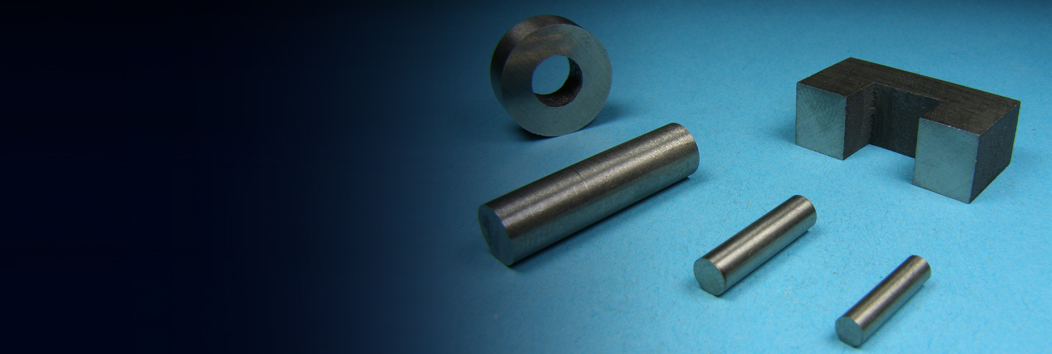

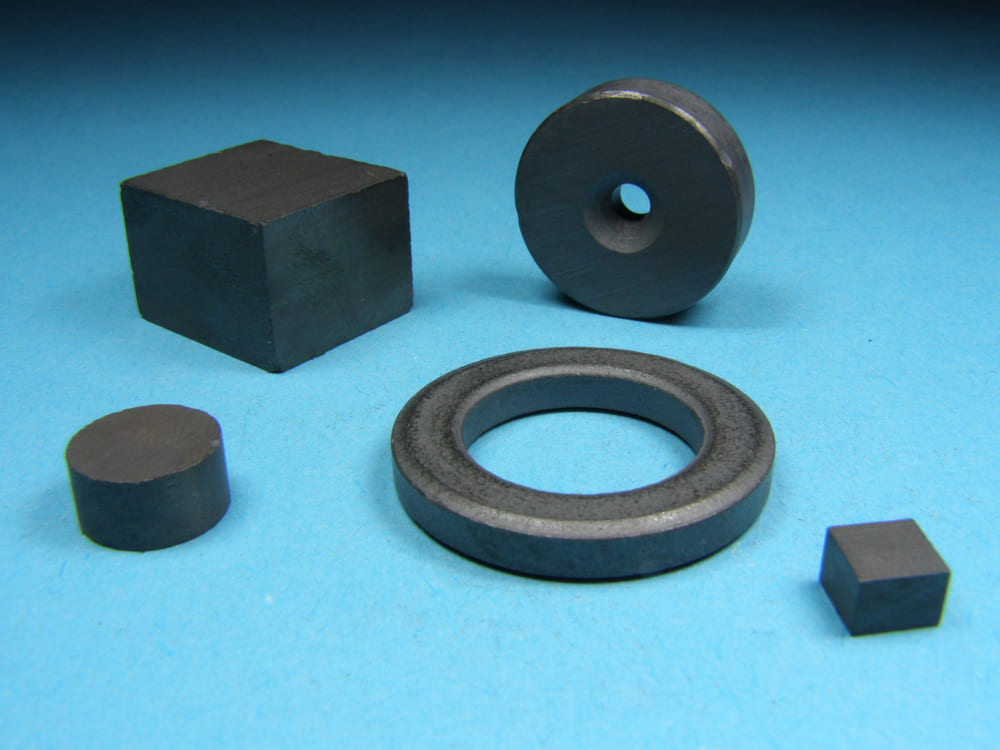

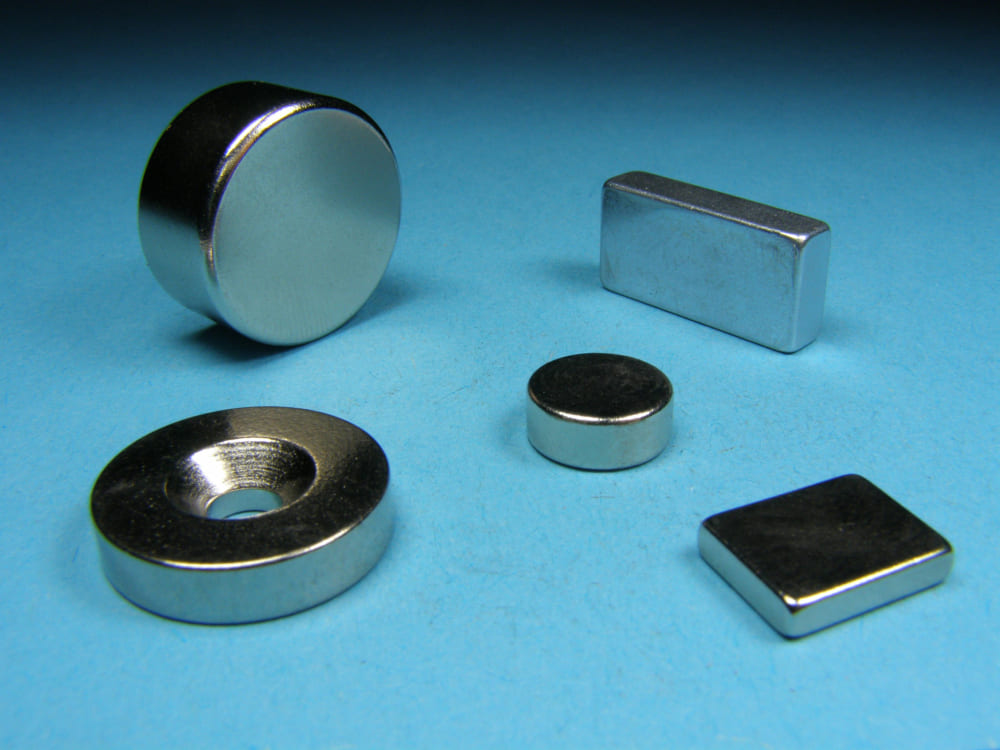

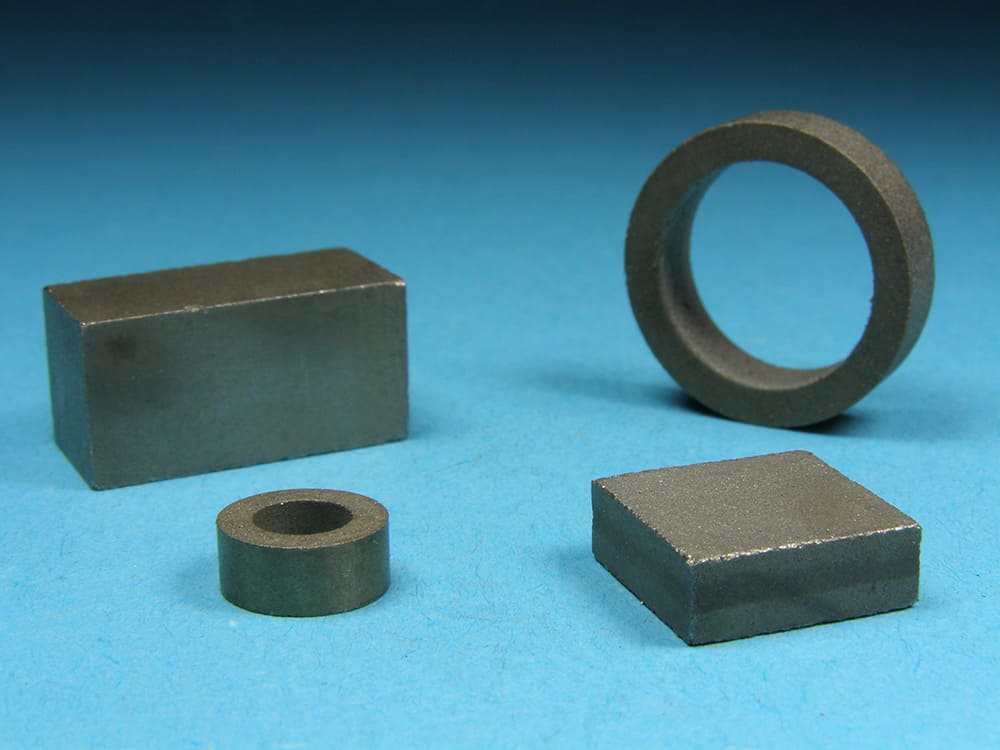

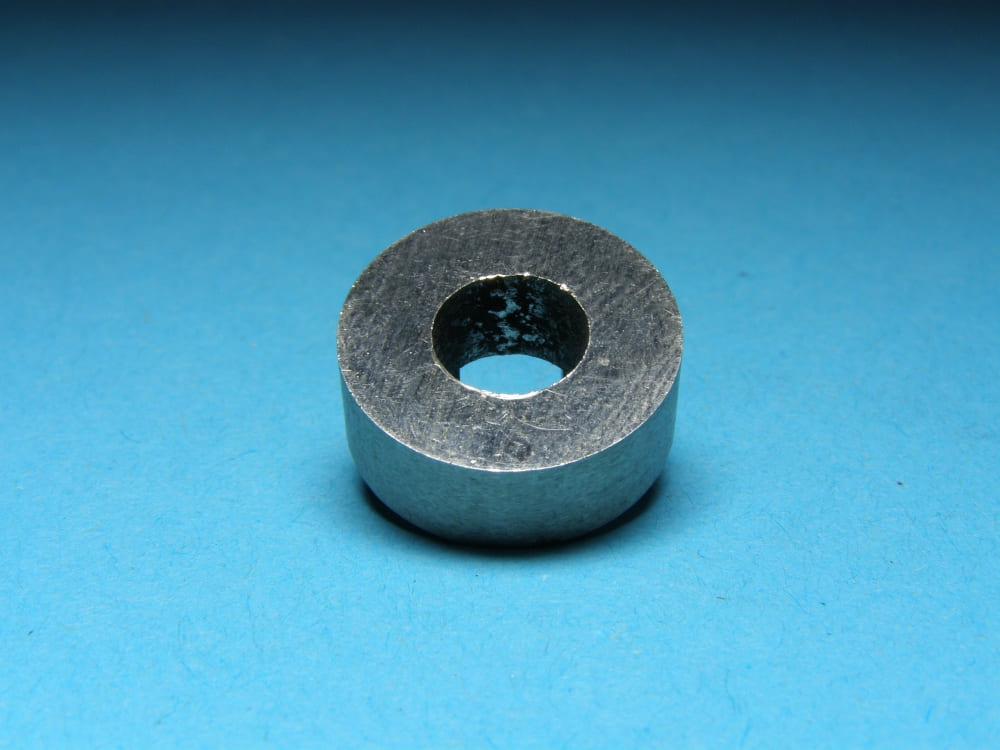

rings

from ø 15 mm to ø 135

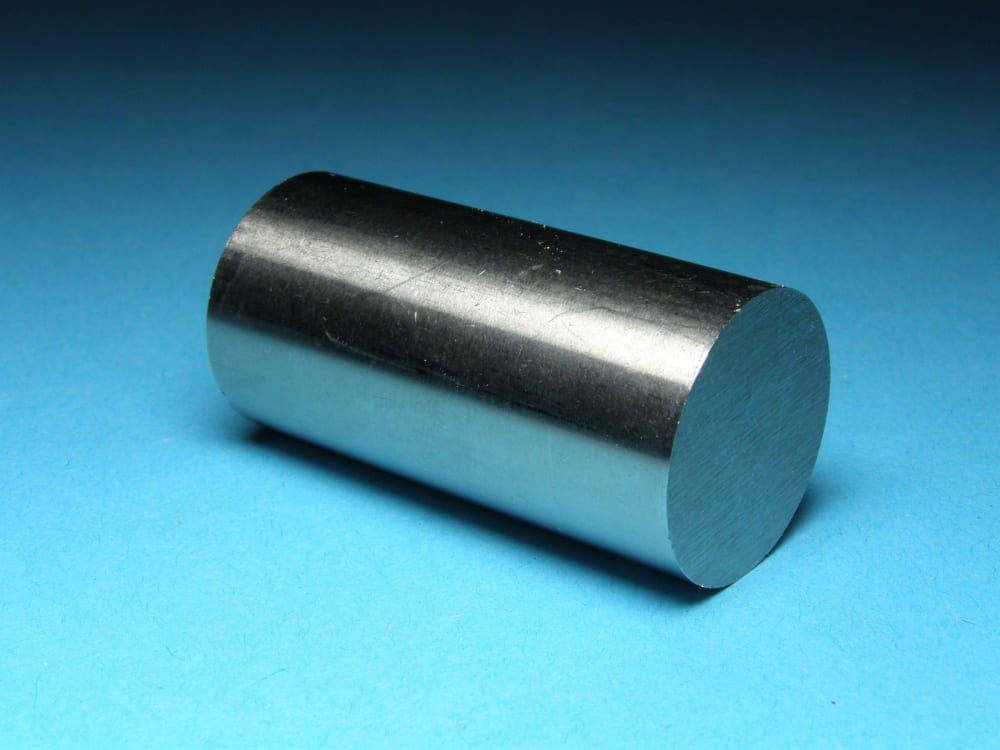

cylinders

from ø 1,7 mm to ø 53 mm

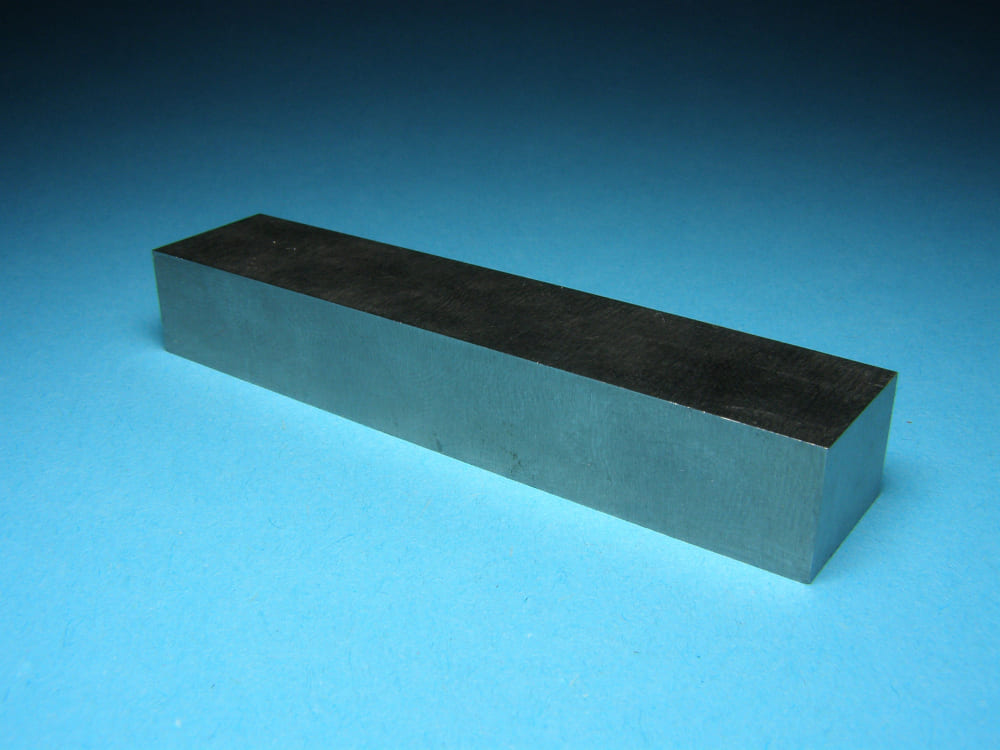

blocks

from 1,5 mm to 240 mm

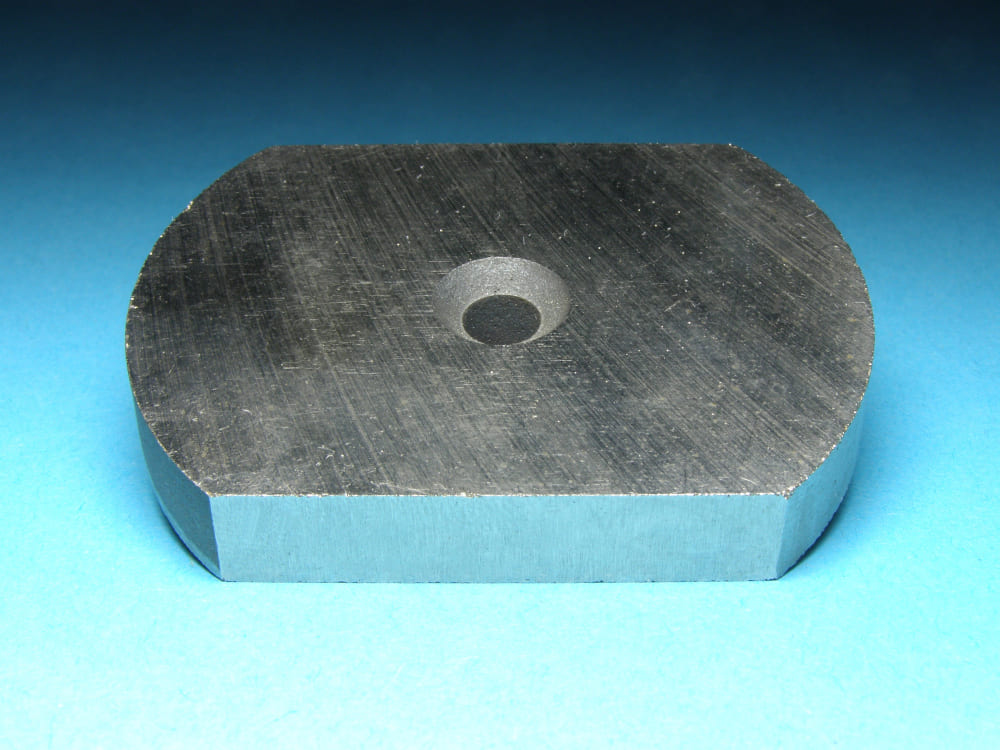

special designs

according to your requirements

Simply ask for your desired magnet. More than 100 different types and dimensions of AlNiCo magnets are available from stock. We are able to manufacture any additional dimension you might require.

Physical and chemical characteristics

Chemical composition [Gew.-%] : 8AL; 14Ni; 24Co; 3,5Cu; RestFe

Density : 7,3 g/cm³

Curie-temperature : 860 °C

max. usage temperature : 450 °C

Expansion coefficient : 11,3 x 10-6/°C

specific electric resistance: 0,5 μ Ohm m

Vickers hardness : HV 10 ca. 500 - 600

Compressive strength : 1200 - 2200 N/mm²

In its chemical resistance the material is similar to highly alloyed steel, but inconsistant in inorganic acids, in sea water or in strongly alkaline solutions. The material is not attacked by organic solvents, alcohols, oils and gasoline. The material is nontoxic and does not pollute the environment. People who are sensitive to nickel can react with the same side effects as other Ni-containing materials. A direct contact with food and the use in the toy industry should be avoided. If necessary the magnets can be coated with plastic or food-suited color. The magnets are very hard and brittle, the edges break easily and they can only be worked on by abrasive procedures (grinding).

Technical Details

Material | Remanence Br [mT] | HCB kA/m | HCj [kA/m] | Bhmax [KJ/m3] | working - temp. [°C] | Curie- temp. °C | Density | |||||

min | max | min | max | min | max | min | max | max | max | g/cm3 | ||

| Alnico 120 | Alnico 1 | 450 | 495 | 56 | 61 | 57 | 63 | 8 | 8 | 500 | 760 | 7,3 |

| Alnico 160 | Alnico 2 | 600 | 660 | 40 | 44 | 41 | 45 | 10 | 11 | 500 | 760 | 7,3 |

| 720 | 792 | 52 | 57 | 53 | 59 | 15 | 17 | 500 | 810 | 7,3 | ||

| Alnico 500 (Guss) | Alnico 5C | 1200 | 1320 | 44 | 48 | 45 | 50 | 33 | 36 | 520 | 7,3 | |

| Alnico 600 | Alnico 5DG | 1200 | 1320 | 48 | 53 | 49 | 54 | 36 | 40 | 550 | 890 | 7,3 |

| Alnico 500 (Sinter) | Alnico 5 | 1100 | 1210 | 53 | 59 | 55 | 60 | 34 | 37 | 550 | 890 | 7,3 |

| Alnico 700 | Alnico 5-7 | 1220 | 1342 | 48 | 53 | 49 | 54 | 38 | 42 | 550 | 890 | 7,3 |

| Alnico 400 | Alnico 6 | 1250 | 1375 | 56 | 61 | 57 | 63 | 47 | 52 | 550 | 890 | 7,3 |

| Alnico 450 (Guss) | Alnico 8 | 900 | 990 | 57 | 63 | 59 | 65 | 28 | 31 | 520 | 890 | 7,3 |

| Alnico 450 (Sinter) | Alnico 8 | 800 | 880 | 110 | 121 | 111 | 122 | 37 | 41 | 520 | 850 | 7,3 |

| 880 | 968 | 110 | 121 | 111 | 122 | 47 | 52 | 520 | 850 | 7,3 | ||

| Alnico 9 | 900 | 990 | 110 | 121 | 111 | 122 | 56 | 61 | 520 | |||

| 700 | 770 | 135 | 149 | 137 | 150 | 34 | 37 | 520 | 850 | 7,3 | ||