Floaters

During sheet metal forming you often have to lift of single sheets from a stack. An excellent solution for ease of handling and to avoid injuries is to magnetically separate ferrous sheets and thin pressings from the top of stacks by the use of floaters or sheet seperators. If a stack of sheet metal ist influenced sideways by a strong magnetic flux, the single sheets are spreaded by repelling forces. You can choose between a standard or a high-perfomce version, according to the sheet dimension, the design of your installation and the amount of oil used on the sheets. We will give you advice in terms of design and location, depending on your application.

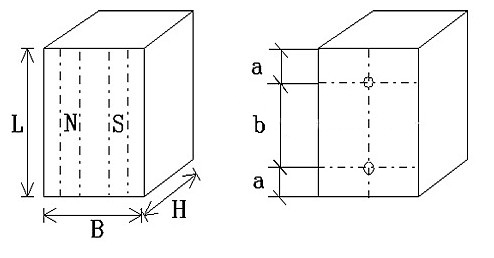

A correct setup is very important for the use of floaters, the stack has to be aligned horizontally to the width B and vertically to L. The seperation effect will be extremely reduced if the floater is turned by 90° on this level. It is even possible that the sheets stick together.

List of Types

Type | dimensions [mm] | sheet thickness | |||||

(for dry sheets) | |||||||

L | B | H | a | b | thread | ||

| BSM75 | 75 | 73 | 28 | 15 | 44 | 2 x M 8 | up to 1 mm |

| BSM275/30 | 275 | 73 | 28 | 56 | 165 | 2 x M 8 | up to 1 mm |

| BSM340 | 342 | 73 | 28 | 47 | 250 | 2 x M 8 | up to 1 mm |

| BSM100 | 104 | 103 | 28 | 20 | 64 | 2 x M 8 | up to 1mm |

| BSM210 | 208 | 103 | 28 | 54 | 100 | 2 x M 8 | up to 2mm |

| BSM310/30 | 308 | 103 | 28 | 55 | 200 | 2 x M 8 | up to 2mm |

| BSM340/30 | 344 | 103 | 28 | 47 | 250 | 2 x M 8 | up to 2mm |

| BSM145 | 143 | 104 | 49 | 24 | 95 | 2 x M 8 | up to 2mm |

| BSM210/50 | 210 | 104 | 49 | 55 | 100 | 2 x M 8 | up to 2mm |

| BSM280/50 | 277 | 104 | 49 | 56 | 165 | 2 x M 8 | up to 2mm |

| BSM310/50 | 310 | 104 | 49 | 55 | 200 | 2 x M 8 | up to 2mm |

| BSM340/1 | 344 | 104 | 49 | 47 | 250 | 2 x M 8 | up to 2mm |

| BSM410/50 | 411 | 104 | 49 | 55 | 150 | 3 x M 8 | up to 2mm |

| BSM440/50 | 444 | 104 | 49 | 47 | 175 | 3 x M 8 | up to 2mm |

| BSM510/50 | 511 | 104 | 49 | 55 | 200 | 3 x M 8 | up to 2mm |